Water Jacket Heat Exchangers

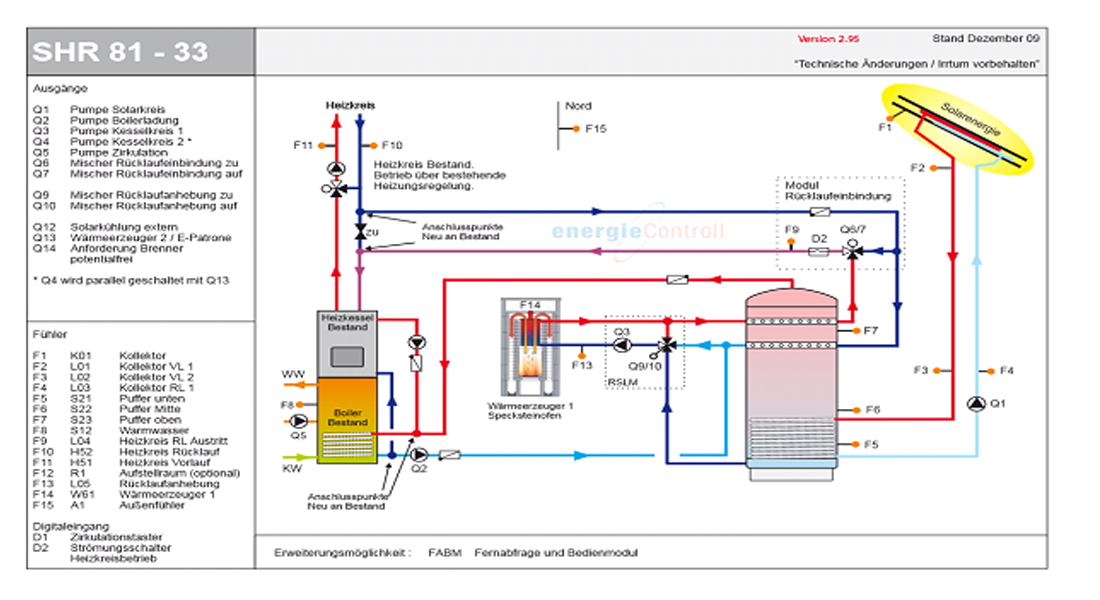

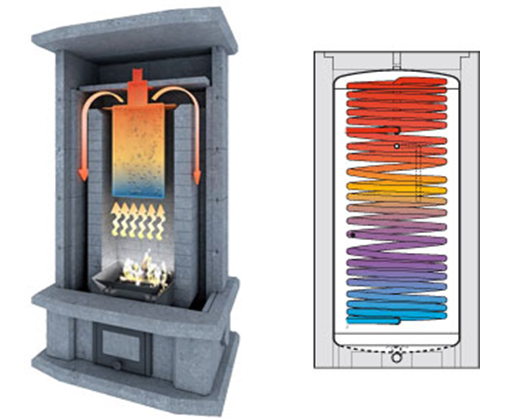

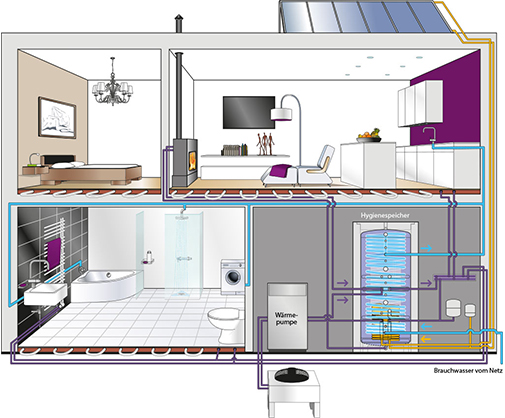

Masonry Heaters are the best wood burning, heating system in the world, for areas where there is a direct line of sight to the heater. If you have a home that does not have an open floor plan and is separated into many separate rooms, you need a system to transfer the enormous amount of heat stored in your masonry heater to those spaces furthest from the heater. The Greenstone Water Jacket Heat Exchanger is the answer. Our unique water jack is a tank with integrated coils, designed to effectively transfer the optimal amount of heat from your firebox to the water and into your in-floor or in-wall radiant heating system. Our digital Whole Home Heating Controller allows you to integrate your Solar Heat, Geothermal and Masonry Heater Water Jacket into a single system, maximizing the output and minimizing the required inputs from each element. This system has changed the way Europeans utilize the best in alternative energy for their homes. We are proud to introduce this game changing technology to North America. Please Call or Email us today for more information.

Product Description WILLACH Heat Exchanger WT 6

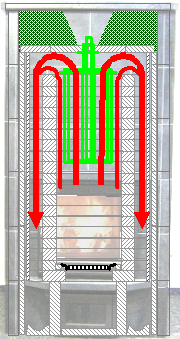

Soapstone masonry heaters have been offered in Germany since approx. 1985. One of the reasons why the soapstone masonry heater is positioned in front places within all offered systems is surely the compact construction and the high efficiency. The consequent and systematical development of the basic heater principle (radiant heater) in connection with improved combustion led to the fact that the Willach soapstone masonry heaters possessthe highest efficiency of 85 % at present. In addition to that the Willach soapstone masonry heaters are manufactured individually, the wishes and ideas of the building owner will be taken into consideration in respect to questions of design and technic. A further special feature is the great variety of different soapstone colours only available by Willach. We dispose of a great stock of different soapstone colours. Regarding the environmental protection our soapstone masonry heatersbelong to the best at all.

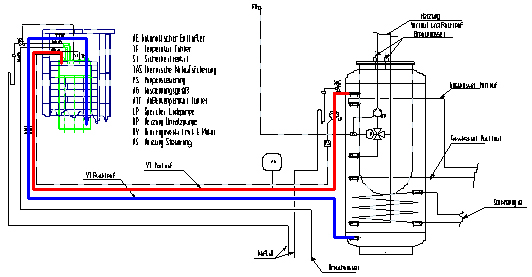

The wonderful heat storage in a soapstone masonry heater encouraged our engineers to think about the possibility how to transport already produced heat into rooms apart from the one where the heater is situated. This should not happen by transportation of hot air but by direct production of hot water in the heater itself. This additional component will increase the total use of the installation many times. The heat exchanger is fixed approx. 600 mm above the firing in a special constructed combustion chamber. The heat exchanger is a welded steel construction (S 235 JRG 2, 16 MO 3) for shells and for tubes (St 35.8.I). Hot flue gases flow through the vertical and special calculated 6 flue gas tubes with high speed. That is the reason why besides the separate bypasses it is normally unnecessary to clean the heat exchanger permanently as it has to be done by horizontal designs. The measured and desired heat efficiency is 7 – 10 kW/h.

Working pressure:- max. 3,0 bar

Temperature:- max. 110°C

Efficiency:- approx. 7 – 10 kW

Safety-valve:- 2,5 bar

Thermal outflow protection:- 95°C

Water-storage:- 21,4 dm3

Nominal heating surface:- 1,23 m3

Overpressure for thermal outflow protection:- max. 10 bar

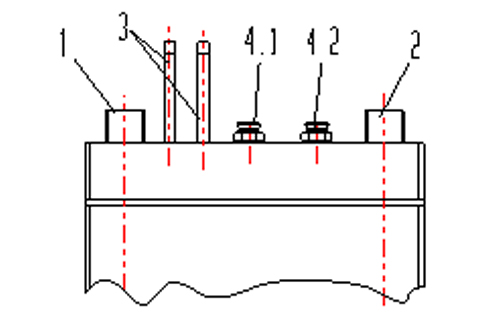

1. + 2. Forward/ Return stroke for buffer storage: R1

3. Thermal discharge safety device

4.1 Temperature measurement

for control of thermal discharge safety device

(longimmersion sleeve)

4.2 Temperature measurement

pump control (short immersion sleeve)

Usually to a buffer storage, which is already supplied by other energy sources such as solar, heat pump, etc. A thermal controlled circulating pump is situated either in the forward or in the return stroke. If the water temperature is higher than 60°C the hot water will be removed from the heat exchanger and transported to the buffer storage.

WT 6

Immersion sleeve for thermal discharge safety device

Immersion sleeve for temperature measurement of the pump control