Installing a masonry heater is a significant investment in your home’s comfort, efficiency, and value. However, before you begin planning your dream heating system, it’s essential to understand the code requirements that govern safe installation. These regulations exist to protect homeowners, ensure proper function, and maintain fire safety standards. Whether you’re building a new home or retrofitting an existing space, knowing these requirements upfront will save time, money, and potential headaches down the road.

Understanding the Regulatory Landscape

Before diving into specific requirements, it’s important to recognize that masonry heater installations are governed by multiple layers of regulation. National codes provide baseline standards, but state and local jurisdictions often have additional or more stringent requirements. This multi-tiered approach means that what’s acceptable in one location may not be permitted in another.

The primary national standard for masonry heaters is ASTM E 1602-94, which provides guidelines for construction and installation. However, your local building department has the final authority on what’s permitted in your area. Some municipalities have embraced masonry heaters and have streamlined approval processes, while others may have inspectors less familiar with these systems.

It’s worth noting that masonry heaters enjoy a unique regulatory status when it comes to emissions. Due to their exceptionally clean-burning characteristics—producing only 1-2 grams per hour of particulate emissions compared to the EPA’s 7.5 g/hr limit for wood stoves—masonry heaters are exempt from EPA certification requirements. This exempt status, recommended by the Cold Climate Housing Research Center in 2009, recognizes the “inherent low emissions” of properly designed masonry heaters.

Clearance Requirements: Critical Safety Distances

One of the most fundamental code requirements involves maintaining proper clearances between your masonry heater and combustible materials. These distances are carefully calculated to prevent heat transfer that could lead to fire hazards, and they’re non-negotiable aspects of safe installation.

Wall Clearances

When placing a Greenstone masonry heater near non-combustible materials such as steel stud, concrete, or brick walls, no clearance to combustibles is required. However, for the optimum performance of your heater, we recommend a minimum gap of 5 inches. This air gap provides several advantages:

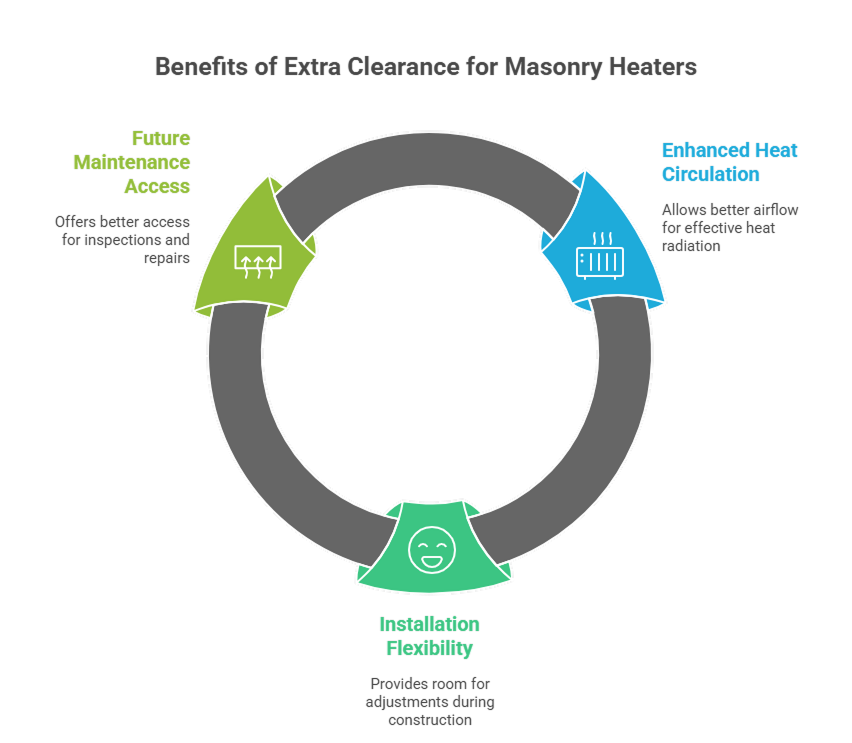

- Enhanced heat circulation: The extra inch allows better airflow behind the unit, enabling the rear surface to radiate heat more effectively into the surrounding room

- Installation flexibility: The additional space makes it easier to work during construction and provides room for minor adjustments

- Future maintenance access: Should any inspection or repair be needed, the extra clearance provides better access to the heater’s rear surface

For combustible materials—including wood framing, furniture, cabinetry, or decorative elements—a minimum four inch air gap is required at the sides and back of your Greenstone Masonry Heater. The top of your heater will require an 8 inch clearance to combustibles. Other brands of masonry heaters may have larger clearance to combustible requirements due to thinner firebox and exchange chamber wall construction.

Floor Protection and Foundation Requirements

The area surrounding your masonry heater’s firebox requires special attention to prevent sparks, embers, or radiant heat from reaching combustible flooring materials. These requirements protect not just during normal operation but also during loading, cleaning, and the occasional escaped ember.

The Hearth Area: Spark Protection Zone

Building codes mandate non-combustible floor protection in what’s known as the spark protection zone—the area immediately in front of and beside the firebox door. ASTM E 1602-94 provides specific dimensional recommendations that most building departments adopt:

- Depth: Minimum 16 inches extending forward from the firebox opening

- Width: Minimum 8 inches extending beyond each side of the firebox opening

- Materials: Non-combustible materials such as tile, stone, brick, or concrete

This hearth protection zone serves multiple purposes. It catches any sparks or embers that might escape when opening the door to load fuel, provides a safe surface for handling hot ashes or dropped wood pieces, and creates a visual boundary that reminds users to exercise caution in the immediate firebox area.

Foundation and Structural Support

Correctly sizing your masonry heater isn’t just about heat output—it’s also about ensuring adequate structural support. Masonry heaters are substantial structures, often weighing several thousand pounds when fully constructed. This massive weight requires proper foundation support, and building codes have specific requirements:

- Floor strength assessment: Existing floors must be evaluated to determine if they can support the heater’s weight, or if reinforcement is necessary

- Foundation options: Depending on your situation, you may need a dedicated concrete pad, reinforced floor framing, or a foundation that extends to the ground

- Load distribution: The weight must be properly distributed to prevent concentrated loads that could damage structural elements

For installations on wood floors, a concrete block insulating barrier can be constructed to distribute the heater’s weight while protecting combustible materials beneath. This approach allows masonry heater installation in locations where a traditional full-depth foundation isn’t feasible. The 16-inch hearth area in front and 8-inch extensions to the sides can then be finished with tile, stone, or other non-combustible decorative materials that complement your interior design.

Chimney and Venting Standards

The chimney system is arguably the most critical component of your masonry heater installation from both a performance and safety standpoint. Proper venting ensures efficient operation, prevents dangerous backdrafting, and safely removes combustion byproducts from your home.

Flue Pipe Requirements

All properly designed masonry heaters require double-wall insulated flue pipe—also known as Class A chimney pipe. This insulated construction provides several essential functions:

- Safety: The double-wall design keeps outer surfaces at safe temperatures, even when interior gases are very hot

- Draft performance: Insulation maintains higher flue gas temperatures, promoting strong draft and efficient venting

- Condensation prevention: Warmer flue walls reduce creosote formation and moisture condensation

The diameter of your flue pipe depends on your heater’s size and design. Smaller masonry heaters typically use 6-inch inside diameter pipe, while larger units require 7-inch or 8-inch inside diameter flue pipes. How masonry heaters work—with their intense, fast burns creating high-temperature exhaust gases—makes proper flue sizing essential for both safety and performance.

Chimney Height and Termination

All Greenstone Masonry Heaters require a minimum flue pipe length of 17 feet. Building codes also specify minimum chimney heights to ensure adequate draft and prevent downdrafts from wind or nearby structures. Generally, chimneys must extend:

- At least 3 feet above the point where they pass through the roof

- At least 2 feet higher than any roof surface within 10 feet horizontally

These height requirements prevent smoke from being drawn back down by wind currents passing over the roof or nearby structures. In areas with complex roof lines or nearby tall trees or buildings, additional height may be necessary for optimal performance.

The chimney termination—the cap or crown at the top—must also meet code requirements for spark arrestors in some jurisdictions, and should always include a rain cap to prevent water entry that could damage the masonry or flue liner.

Through-Wall and Through-Ceiling Penetrations

Anywhere your chimney pipe passes through combustible construction—walls, floors, or ceilings—specific clearances and protection methods must be employed. These penetrations require:

- Listed chimney support boxes or thimbles designed for your pipe diameter

- Proper clearances to combustible framing (typically 2 inches to wood framing)

- Fire-stops at floor penetrations to prevent fire spread between floors

- Proper flashing and weatherproofing where the chimney exits the roof

These penetrations are critical inspection points, and inspectors will carefully verify that they meet all applicable code requirements.

Combustion Air Requirements

Modern energy-efficient homes are built tight to reduce heating and cooling costs, but this tightness can create combustion air challenges for any fuel-burning appliance. Building codes increasingly require dedicated combustion air provisions for masonry heaters.

Building Permit and Inspection Process

Understanding the permit and inspection process helps ensure smooth installation without delays or complications.

Obtaining Permits

Nearly all jurisdictions require building permits for masonry heater installations. The permit process typically involves:

- Submitting detailed installation plans showing heater location, dimensions, and clearances

- Providing manufacturer specifications or custom design documentation

- Paying permit fees based on project scope

- Scheduling required inspections at appropriate construction phases

Working with experienced masonry heater professionals streamlines this process significantly, as they understand local requirements and maintain relationships with building departments.

Insurance and Liability Considerations

While not strictly “code requirements,” insurance considerations are closely related and equally important to address before installation.

Homeowner’s Insurance

Contact your insurance provider before beginning installation to:

- Verify that masonry heaters are covered under your policy

- Determine if any policy modifications or additional coverage is needed

- Understand documentation requirements (inspection certificates, installer credentials, etc.)

- Confirm whether installation affects your premiums

Most insurance companies view properly installed masonry heaters favorably due to their safety record, but it’s essential to communicate with your provider proactively.

Regional and Climate-Specific Considerations

Building codes sometimes include regional variations based on local climate, fire risk, or other environmental factors.

Fire-Prone Areas

In regions with high wildfire risk, additional requirements may include:

- Enhanced spark arrestors on chimney caps

- Increased clearances to exterior combustible materials

- Special consideration for ash disposal areas

- Requirements for defensible space around the structure

Seismic Zones

In earthquake-prone regions, codes may require:

- Enhanced structural anchoring of the masonry mass

- Flexible connections in the chimney system to accommodate movement

- Engineering review of the foundation design

Understanding these regional variations early prevents costly modifications later.

Planning for Success

Successfully navigating masonry heater code requirements requires early planning and professional guidance. Start by:

- Researching local requirements: Contact your building department to understand specific local codes

- Consulting professionals: Work with experienced masonry heater installers familiar with your area

- Planning adequate budget: Include permit fees, potential structural modifications, and professional installation

- Allowing sufficient timeline: Permit approval and inspections add time to project schedules

The complexity of code requirements shouldn’t discourage you from pursuing a masonry heater installation. Rather, view these regulations as safeguards ensuring your heating system will provide safe, reliable service for generations. With proper planning, professional guidance, and attention to detail, navigating code requirements becomes a manageable part of creating your dream heating solution.

Ready to begin planning your code-compliant masonry heater installation? Our experienced team understands the intricate requirements across multiple jurisdictions and can guide you through every step of the process, from initial planning through final inspection approval.

Frequently Asked Questions

Do I need a permit to install a masonry heater?

Yes, nearly all jurisdictions require building permits for masonry heater installations. The permit ensures your installation meets local safety codes and includes necessary inspections at various stages of construction.

How far must a masonry heater be from my wall?

For combustible walls like wood stud and drywall, the minimum clearance is 4 inches, though 5 inches is recommended for better heat circulation.

What kind of chimney pipe do masonry heaters require?

All masonry heaters require double-wall insulated flue pipe (Class A chimney). Smaller units typically use 6-inch diameter pipe, while larger heaters need 7-inch or 8-inch diameter pipes for proper venting.

Can I install a masonry heater on a wood floor?

Yes, with proper preparation. A concrete block insulating barrier can be installed to distribute the heater’s weight and protect combustible flooring. The hearth protection zone must still extend 16 inches forward and 8 inches to each side of the firebox.

Do masonry heaters need EPA certification?

No, masonry heaters are exempt from EPA certification requirements due to their inherently low emissions (1-2 g/hr compared to the 7.5 g/hr EPA limit). This exempt status recognizes their exceptionally clean-burning characteristics.

Leave a Reply