When it comes to home heating solutions, efficiency isn’t just about saving money—it’s about maximizing the energy content of your fuel while minimizing waste and environmental impact. Masonry heaters stand out in the world of wood-burning appliances with their exceptional combustion efficiency rates that regularly exceed 90%. But what does this really mean, and how do these ancient heating systems achieve such remarkable performance?

In this comprehensive guide, we’ll break down the science behind masonry heater efficiency, compare them to other heating systems, and explore why they’re becoming increasingly popular among environmentally conscious homeowners seeking sustainable heating solutions.

Understanding Combustion Efficiency: What the Numbers Really Mean

Before diving into masonry heater specifics, it’s important to understand what combustion efficiency actually measures. Combustion efficiency refers to how completely a heating appliance converts the potential energy in fuel into usable heat. When wood burns, it releases energy stored in its chemical bonds. However, not all of this energy necessarily heats your home.

In an inefficient system, much of that energy escapes up the chimney as hot gases, unburned particles, or creosote. The efficiency rating tells you what percentage of the fuel’s energy content actually becomes heat that warms your living space.

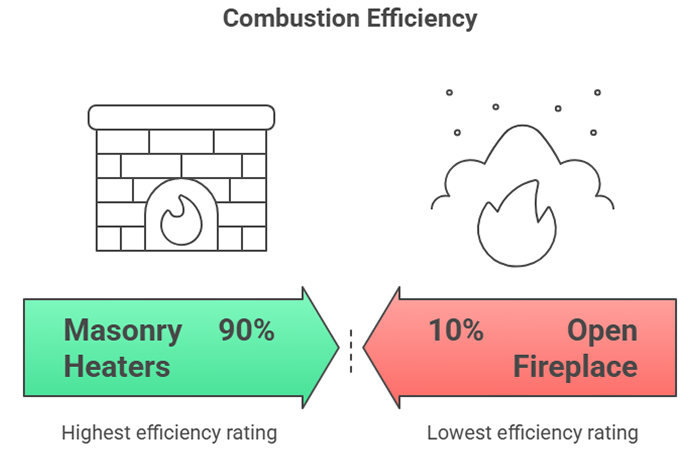

A traditional open fireplace typically operates at just 10-30% efficiency. This means that for every cord of wood you burn, 70-90% of its heating potential literally goes up in smoke. A conventional wood stove performs better at 50-70% efficiency, while EPA-certified modern wood stoves can reach 70-80%.

Masonry heaters, however, routinely achieve 80-90% combustion efficiency, with some designs exceeding 90%. This dramatic difference translates to real-world benefits: less wood consumption, lower heating costs, and significantly reduced emissions.

The Science Behind Superior Efficiency

The extraordinary efficiency of masonry heaters stems from their unique design and operating principles. Unlike conventional heating systems, masonry heaters combine three critical elements that work synergistically to maximize combustion and heat retention.

High-Temperature Combustion

The first key to masonry heater efficiency is extremely high combustion temperatures. When you light a fire in a masonry heater, you’re not creating a smoldering, smoky fire like you might in a traditional fireplace. Instead, you build a hot, fast-burning fire that reaches temperatures of 1,100-1,500°F or even higher in the combustion chamber.

These elevated temperatures are crucial because complete combustion requires sufficient heat. At lower temperatures, wood releases volatile gases that don’t fully burn, creating smoke, creosote, and wasted energy. At the high temperatures achieved in a masonry heater, nearly all of these volatile compounds combust completely, releasing their full energy content and producing minimal smoke or particulate matter.

The clean burn is so complete that many masonry heaters produce virtually no visible smoke from the chimney after the first few minutes of firing. If you see thick smoke pouring from a masonry heater chimney, something is wrong—either the fire wasn’t started properly, the wood is too wet, or there’s a design flaw.

The Long Heat Exchange Path

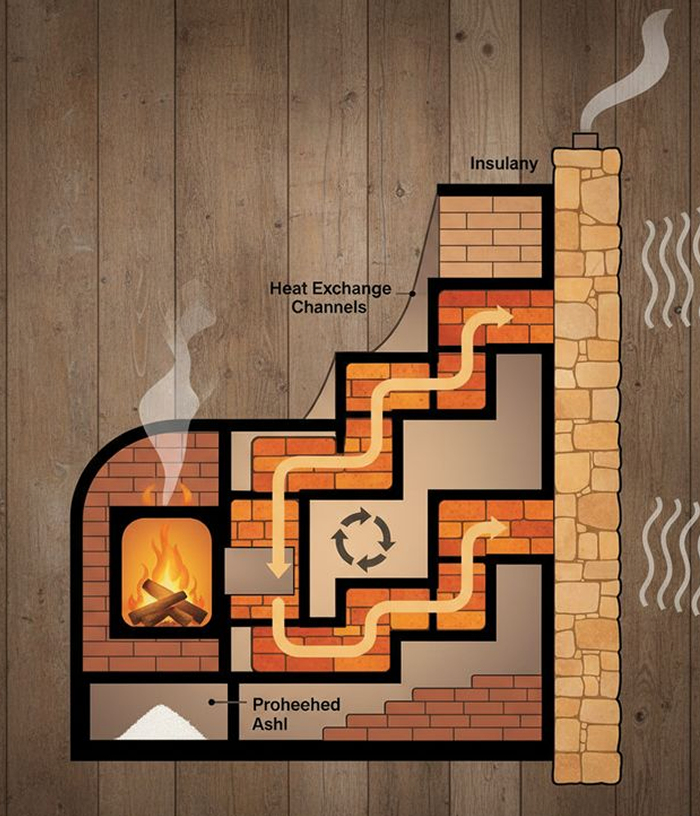

The second efficiency factor is the ingenious internal architecture of masonry heaters. After combustion, the hot gases don’t shoot straight up a chimney as they do in a fireplace. Instead, they travel through an elaborate maze of channels, chambers, and baffles within the masonry mass.

This circuitous path serves a critical function: it gives the hot exhaust gases time to transfer their heat to the surrounding masonry. By the time the gases finally exit through the chimney, they’ve cooled dramatically—often to just 200-400°F compared to 1,000°F+ in a conventional fireplace.

Think of it like this: in a traditional fireplace, you’re essentially heating the outdoors with a very expensive indoor fire. In a masonry heater, you’re capturing that heat and storing it where it can actually warm your home.

The exact configuration of these internal channels varies by design. Some masonry heaters use vertical channels, others use horizontal bell chambers, and many combine multiple approaches. The fundamental principle of masonry heater design remains constant: maximize the surface area contact between hot gases and thermal mass to extract as much heat as possible before exhaust.

Thermal Mass Storage

The third element of masonry heater efficiency is the massive heat storage capacity. A typical masonry heater weighs between 1,000 and 5,000 pounds or more, constructed from materials specifically chosen for their heat retention properties: brick, stone, soapstone, and tile.

This enormous thermal mass acts like a battery for heat energy. During the short, hot fire (typically 1-2 hours), the masonry absorbs tremendous amounts of thermal energy. Then, over the next 12-24 hours, it slowly releases this stored heat into your living space through gentle radiation.

This storage effect essentially decouples heat production from heat delivery. You create heat intensely and efficiently during the burn, then distribute it gradually and evenly throughout the day. This is fundamentally different from conventional heating systems that must run continuously to maintain temperature, starting and stopping inefficiently throughout the day.

Comparing Masonry Heater Efficiency to Other Heating Systems

To truly appreciate masonry heater efficiency, it helps to compare them directly to alternative heating options. Let’s examine how they stack up against common residential heating systems.

Traditional Fireplaces: 10-30% Efficiency

Open fireplaces are notoriously inefficient. Most of the heat escapes up the chimney, and they can actually make your home colder by drawing warm air from the room and exhausting it outdoors. Even with glass doors and outside air intakes, fireplace efficiency rarely exceeds 30%. They’re lovely to look at and provide ambiance, but terrible as primary heating sources. Learn more about why traditional fireplaces waste energy.

Conventional Wood Stoves: 50-70% Efficiency

Standard wood stoves improve significantly on fireplace performance by containing the fire in a metal box that radiates heat into the room. However, they still lose considerable heat up the chimney, especially during the smoldering phase that characterizes how most people operate them. The metal also heats and cools quickly, requiring frequent reloading to maintain temperature.

EPA-Certified Wood Stoves: 70-80% Efficiency

Modern EPA-certified wood stoves use advanced combustion technology—catalytic converters or secondary combustion chambers—to burn more completely. These achieve respectable efficiency but still fall short of masonry heaters. They also produce more significant temperature swings and require more frequent attention.

Pellet Stoves: 70-85% Efficiency

Pellet stoves burn manufactured pellets with automated feed systems, achieving good efficiency through controlled combustion. However, they require electricity to operate, produce less comfortable heat than radiant systems, and depend on processed fuel. Many homeowners seeking sustainable heating alternatives prefer the renewable simplicity of cordwood.

Masonry Heaters: 80-90%+ Efficiency

Masonry heaters achieve superior efficiency through complete combustion combined with maximum heat extraction and storage. They use less wood than any other wood-burning option to produce the same heat output, and their radiant warmth is widely considered the most comfortable heating available.

Real-World Performance: What 90% Efficiency Means for Homeowners

Understanding efficiency percentages is one thing, but what do these numbers mean in practical terms for your home, your budget, and your daily life?

Reduced Fuel Consumption

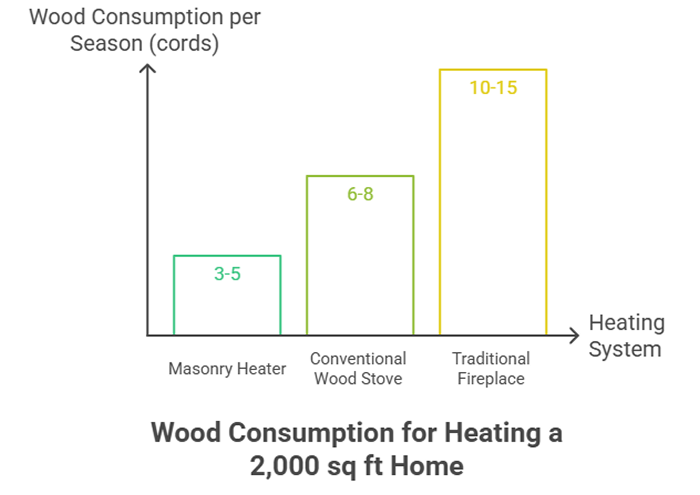

The most immediate benefit of high efficiency is using less wood. A well-designed masonry heater can heat a 2,000-square-foot home in a moderate climate with just 3-5 cords of wood per heating season. Compare this to 6-8 cords for a conventional wood stove or 10-15 cords for a traditional fireplace heating the same space.

At current firewood prices of $200-400 per cord in many areas, this difference adds up quickly. Even accounting for the higher initial installation cost, the fuel savings alone can justify a masonry heater investment over its multi-decade lifespan.

Environmental Benefits

Burning less wood means fewer emissions, even beyond the already-clean burn of high-efficiency combustion. Masonry heaters produce minimal particulate matter—often measured at less than 5 grams per hour compared to 20-40 grams for conventional wood stoves.

This clean burn matters for both local air quality and global environmental concerns. Wood heating can be carbon-neutral when properly managed, but only if the combustion is efficient and complete. The environmental advantages of masonry heaters extend beyond just emissions to include sustainable forest management and reduced fossil fuel dependence.

Comfort and Convenience

High efficiency doesn’t just mean using less fuel—it also means more consistent comfort. Because the thermal mass stores heat so effectively, masonry heaters maintain stable temperatures with minimal intervention. One or two fires per day typically suffice, compared to constant feeding required by conventional wood stoves.

The radiant heat produced feels warmer at lower ambient temperatures than forced air or convective heat. Many masonry heater owners report being comfortable at 65-68°F room temperature, whereas they might need 70-72°F with conventional heating. This represents additional energy savings beyond the fuel efficiency itself.

Factors That Influence Masonry Heater Efficiency

While masonry heaters are inherently efficient, actual performance varies based on several critical factors. Understanding these can help you maximize your system’s effectiveness.

Design Quality

Not all masonry heaters are created equal. Proper design requires specialized knowledge of combustion dynamics, heat transfer, and masonry construction. A well-designed heater optimizes the relationship between firebox size, internal channel configuration, and thermal mass proportions.

Working with an experienced masonry heater designer or mason who specializes in these systems is essential. Organizations like the Masonry Heater Association of North America (MHA) maintain directories of qualified professionals who understand the principles of effective masonry heater construction.

Wood Quality and Moisture Content

Even the most efficient heater can’t overcome poor fuel. Wood moisture content dramatically affects combustion efficiency. Properly seasoned firewood should have moisture content below 20%, ideally 15% or less.

Wet or green wood requires significant energy just to evaporate moisture, lowering effective efficiency and creating creosote. It also produces incomplete combustion and excessive smoke. Using a moisture meter and ensuring wood is seasoned for at least one year (two years for dense hardwoods) is crucial for achieving optimal efficiency.

Operating Technique

Masonry heaters require different operating techniques than conventional wood stoves. The goal is a hot, fast fire that burns completely in 1-2 hours, not an all-day smolder. Proper technique includes using enough kindling, building an appropriately sized fire for the conditions, and allowing complete combustion before closing off air supplies.

Learning these best practices for masonry heater operation may take some adjustment for those accustomed to conventional wood burning, but mastering them is key to achieving the advertised efficiency numbers.

Installation and Integration

How the masonry heater integrates with your home affects practical efficiency. Placement should maximize radiant heat distribution to living spaces. Proper clearances, adequate combustion air supply, and appropriate chimney height all influence performance.

In well-insulated, open-plan homes, a single centrally-located masonry heater can serve as the primary heat source. In older, drafty homes or those with closed-off rooms, supplemental heating may be necessary, reducing the overall system efficiency advantage.

Understanding Code Requirements for Safe, Efficient Installation

Proper installation isn’t just about safety—it directly impacts efficiency. Watch this comprehensive guide on masonry heater code requirements:

Understanding clearances, proper chimney sizing, and building code compliance ensures your masonry heater operates at peak efficiency while meeting all safety standards.

Measuring and Verifying Efficiency

How do we actually know masonry heaters achieve 90%+ efficiency? These numbers aren’t just marketing claims—they’re based on rigorous testing and established measurement protocols.

Laboratory Testing

Independent testing laboratories measure combustion efficiency using sophisticated equipment that analyzes exhaust composition, temperature differentials, and heat output. These tests follow standardized protocols that account for various operating conditions and fuel types.

The Masonry Heater Association maintains efficiency standards and many manufacturers publish verified test results. When evaluating a masonry heater design, asking for documented efficiency testing provides objective performance data.

Field Performance

While laboratory conditions provide controlled comparisons, real-world performance depends on the factors discussed earlier. Many masonry heater owners track their actual wood consumption over seasons, providing empirical evidence of efficiency.

Online forums and owner communities share experiences comparing fuel use before and after installing masonry heaters, generally confirming the substantial efficiency advantages in practical applications.

The Future of High-Efficiency Wood Heating

As concerns about energy costs, energy independence, and environmental sustainability grow, interest in ultra-efficient wood heating continues to increase. Masonry heaters represent proven technology that aligns with modern priorities: renewable fuel, minimal emissions, exceptional efficiency, and comfortable, healthy heat.

Contemporary innovations are making these systems even better. Some designers are incorporating automated air supply controls, temperature monitoring, and hybrid systems that combine masonry heaters with other renewable technologies like solar thermal or heat pumps.

The evolution of masonry heater technology continues to refine efficiency while maintaining the fundamental advantages that have made these systems effective for centuries.

Conclusion: Efficiency That Makes a Difference

When we talk about masonry heater efficiency exceeding 90%, we’re describing a heating system that genuinely maximizes the energy potential of wood fuel. This isn’t just about impressive numbers—it’s about practical benefits that affect your daily comfort, your heating costs, and your environmental footprint.

The combination of complete high-temperature combustion, extensive heat extraction through internal channels, and thermal mass storage creates efficiency that other wood-burning appliances simply cannot match. For homeowners committed to wood heating, particularly those seeking sustainable, off-grid, or resilient heating solutions, masonry heaters offer unparalleled performance.

Whether you’re building a new home, renovating an existing one, or simply exploring alternative heating options, understanding masonry heater efficiency helps you make informed decisions. The higher upfront investment buys you decades of superior performance, reduced fuel consumption, and the incomparable comfort of radiant heat—all while knowing you’re heating your home in the most efficient way possible with renewable wood fuel.

The 90%+ combustion efficiency of masonry heaters isn’t just a technical specification—it’s a testament to centuries of refined design and a compelling reason to consider this exceptional heating technology for your home.

Ready to experience 90%+ heating efficiency in your home? Contact us discuss custom masonry heater options designed for maximum efficiency and comfort.

Leave a Reply